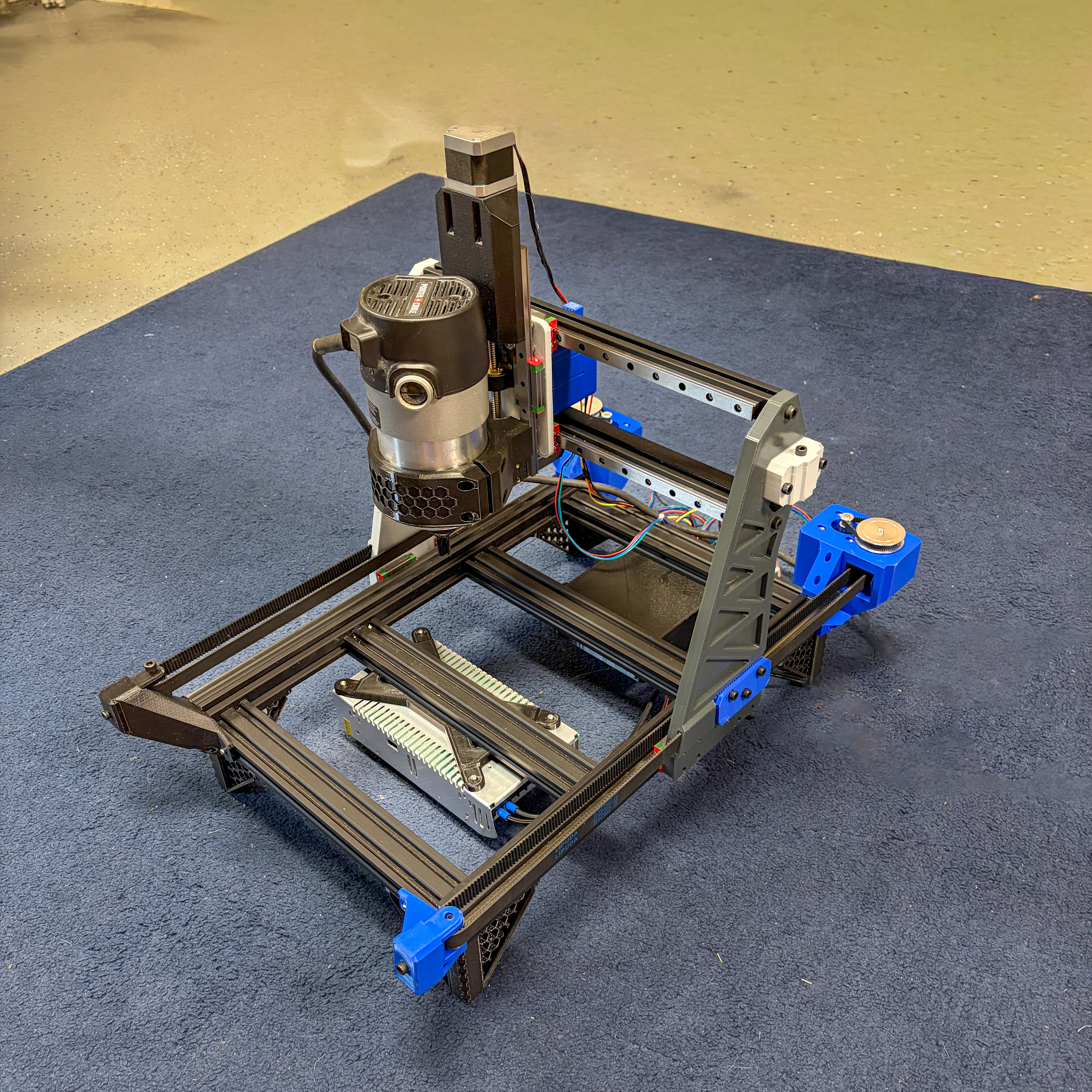

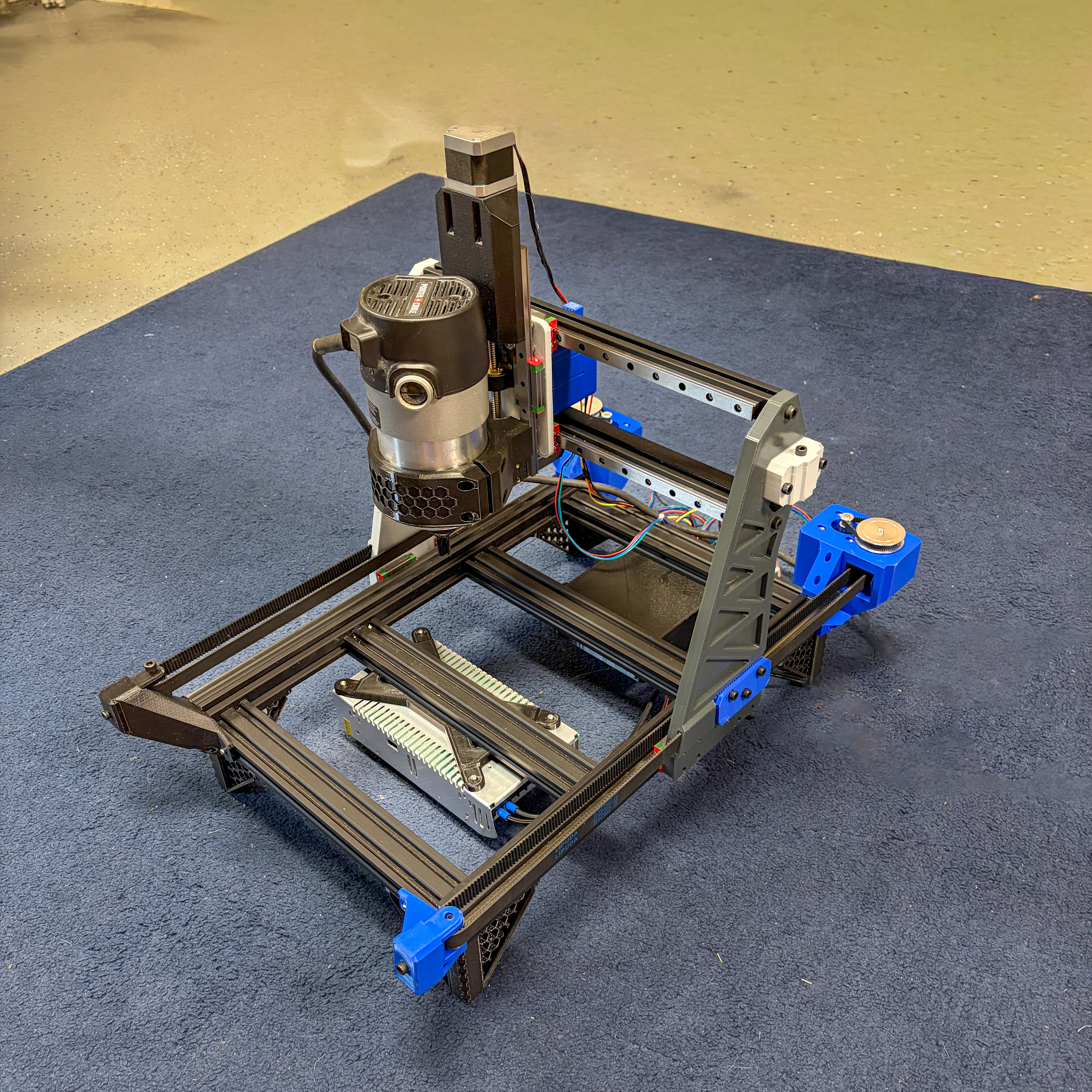

Current State

All axes (X,Y,Z) are moving and are somewhat calibrated.

It needs a few design revisions, specfically to the router mount.

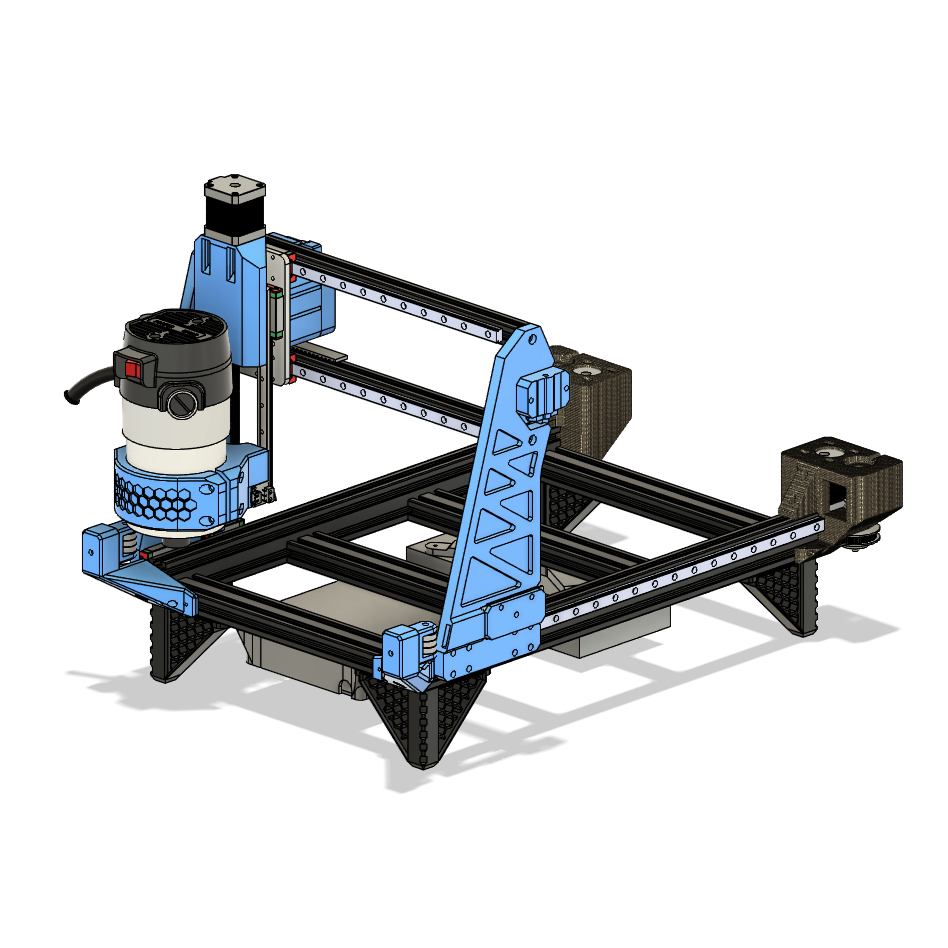

Self-designed, 3D Printed, desktop-sized

Around 2022, my high school robotics team purchased an entry level CNC router for about $7,000. Throughout the next few years, I spearheaded the project by teaching myself, and later others, how to run this new machine efficently and with good results. Applying this process to our robot build process significantly decreases our prototyping and manufactruring time along with increasing precision.

In Spring of 2025, I realized that I would soon be graduating and would no longer have access to one of these machines. This, along with my immense urge to have a larger and larger collection of cool toys... *cough* *cough* tools... led me to start designing and building my own, just a little be cheaper and thermore much smaller.

All axes (X,Y,Z) are moving and are somewhat calibrated.

It needs a few design revisions, specfically to the router mount.

Revise and reprint Router Mount, figure out endstops (physical and virtual), install spoil boards, test cuts!

Below is a list of major milestones during this project with images. The top is the most recent.